How do you choose the right medium voltage cable splice?

The power grid must become greener, smarter, more reliable—and evolve faster than ever. But what does this energy transition mean for connecting underground medium voltage cables? More importantly, which splicing technology performs best in a decentralised generation network? One thing is certain: choosing the right medium voltage cable splice has never been more critical.

Comparing cable splicing technologies

Today, you can choose from a range of splicing technologies—each with its own strengths. For instance, heat shrink technology involves using a gas torch to shrink the splice tightly around the connector. Cold shrink technology, on the other hand, uses a pre-stretched body that contracts once the spiral cord is removed. Alternatively, liquid insulation technology seals the connection inside a protective housing filled with liquid silicone. As splicing requirements become more complex, understanding these differences is essential.

What does sustainability mean for the underground cable network?

Grid operators play a key role in selecting the right products for the electricity infrastructure. Political and climate goals make it clear: we must accelerate the transition to sustainable energy. That means moving away from fossil fuels toward clean sources such as solar, wind, and hydro power. However, this shift places new demands on the existing cable network.

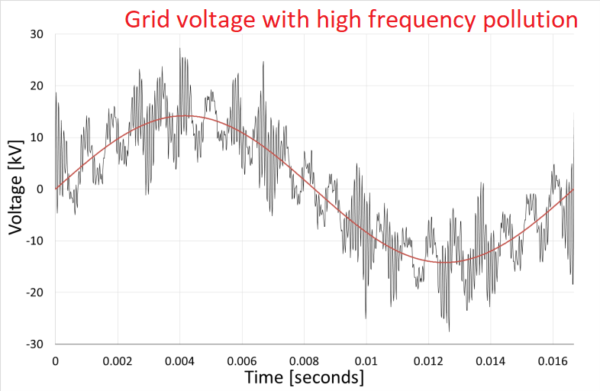

In short, cables now carry more load than they were originally designed for. Locally generated energy—whether from solar parks, wind farms, or hydro stations—feeds back into the same grid. Consequently, electric current often flows in both directions, creating “two-way traffic” in the cables. Additionally, transmissions use power electronics that include high-frequency switching elements. These, in turn, introduce high-frequency harmonics into the network.

What do thermal load and harmonics mean for medium voltage cable splices?

Harmonics, which are integer multiples of the standard 50 Hz frequency, may seem harmless. However, they can trigger a range of negative effects—thermal, mechanical, chemical, and electrical. All of these are interconnected and can compromise cable performance over time. To explore this further, see our technical paper: The Future Challenges for Cable Accessories in Medium Voltage Networks.

Harmonic contamination in the grid significantly increases the risk of partial discharges (PDs). These tiny electrical arcs attack the insulation material—particularly XLPE. You can think of them as miniature lightning strikes. Each one damages the insulation layer, creating microscopic erosion and weak spots. Eventually, this can lead to cable and splice failure.

Traditional shrink splices, often made from polymers, are especially vulnerable to PDs. Electrical treeing tends to occur around interfaces or air pockets. Once breakdown begins, the damage is usually irreversible.

Why Liquid silicone splices offer a smarter solution

Liquid silicone cable splices provide a sustainable, high-performance alternative. They offer several critical advantages:

-

Self-Healing Properties: If a partial discharge does occur, the silicone material can repair itself, preventing long-term degradation.

-

Fewer Air Voids: The liquid fills every gap in the splice housing, virtually eliminating air pockets that could trigger discharges.

-

Superior Moisture Resistance: Silicone is hydrophobic. It forms a tight, water-resistant seal—even in high-humidity environments. Upon contact with water, a flexible insulating rubber forms.

-

Enhanced Dielectric Strength: The dielectric properties of liquid silicone are equal to—or better than—those of polymeric cable materials.

-

Easy and Safe Installation: Splices can be installed quickly without flame or heat, making them safer and faster to deploy in the field.