Extend the lifespan of your PILC grid

Aging Paper Insulated Lead Covered (PILC) cable grids present a growing challenge for utilities worldwide. As infrastructure ages and replacement costs soar, extending the service life of PILC cables becomes not just a priority—but a necessity. At Lovink, we specialize in helping utilities optimize their legacy assets while ensuring safety, reliability, and long-term performance.

Understanding the challenges of PILC cable aging

PILC grids were once the backbone of underground distribution systems, but with many networks now reaching or exceeding their design life, the risk of failure increases significantly. Common issues include:

- Drying out of the paper insulation

- Lead sheath corrosion

- Electrical degradation at joints and terminations

- High cost and complexity of full cable replacement

Rather than face immediate, expensive overhauls, utilities are turning to smarter solutions to extend PILC cable service life—safely and effectively.

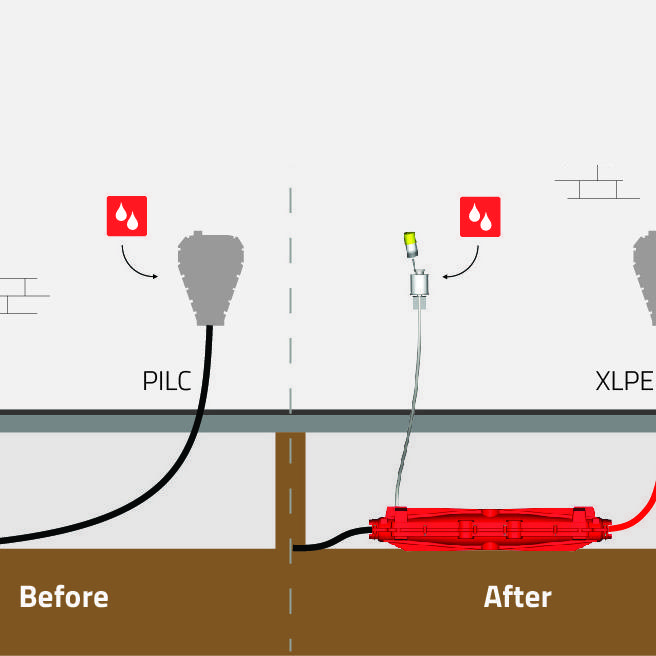

The solution: Lovink’s Oil Refill splice

A critical component in maintaining PILC grids is ensuring the dielectric quality of the cable insulation—especially in oil-filled systems. Lovink’s Oil Refill splice is a revolutionary solution designed to restore and preserve oil-filled PILC cable performance.

- Restores dielectric strength by replenishing cable insulation oil

- Prevents further degradation through hermetically sealed, corrosion-resistant construction

- Cost-effective and minimally invasive, avoiding the need for cable replacement

- Compatible with existing infrastructure and adaptable to various configurations

- Reduces downtime and maintenance costs

With Lovink’s Oil Refill Joint, utilities can extend the operational lifespan of PILC cables by years—improving ROI and network stability.